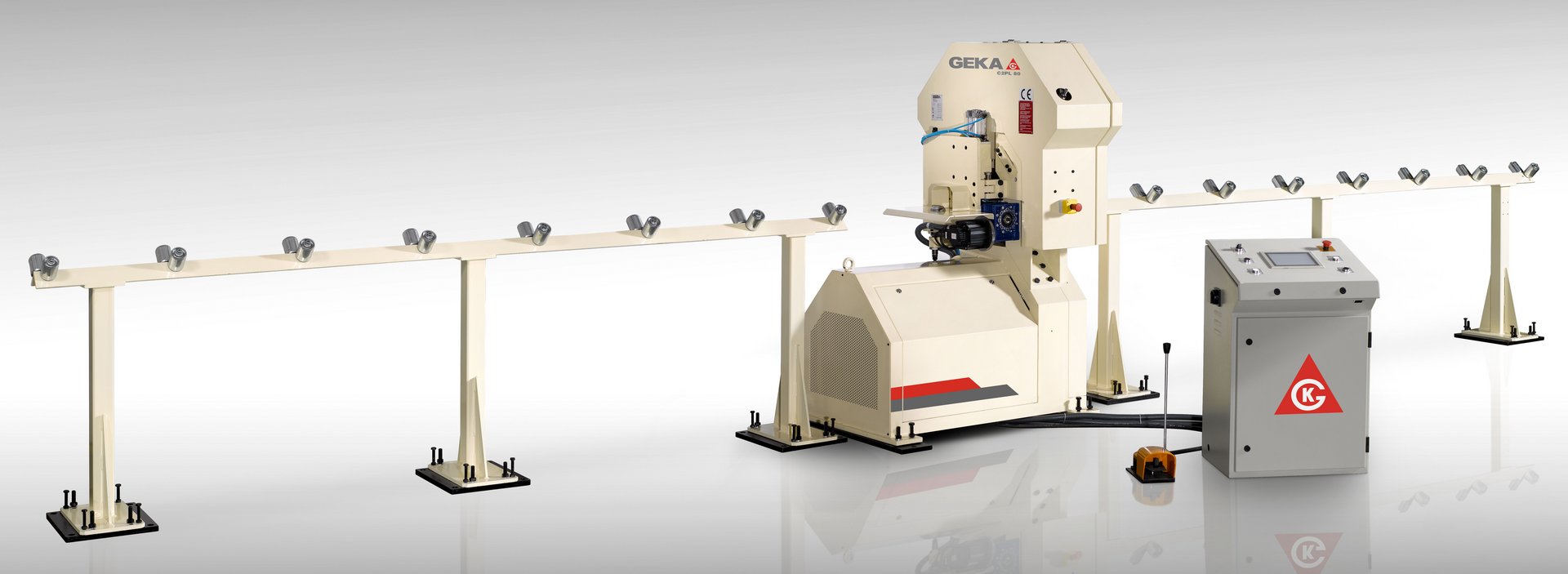

General characteristics

| Punching power | 170 ton |

| Min. angle steel | 40x40x4 mm |

| Max. angle steel | 65x65x7 mm |

| Amount of punching units | 2 |

| Max. diameter at sheet thickness (mild steel) | 25/5 bzw- 18/7 mm |

| Cutting power | 350 to |

| Motor | 5 kW |

| Max. pressure | 265 bar |

| Oiltank | 70 l |

Description

Automatic line for punching and sharing

angle

Standard equipment:

infeed/outfeed conveyers

idle rollers

3 conveyers each 3,3 m

for feeding angles up to 12 m length

working units:

roller feed measuring system

feed by roller wheel (brushless moto), rotary encoder

no time loss for measuring

feeding speed variable from 0 to 36 m/min

positioning accuracy in X axis 0,25 mm + 0,15 mm per meter

the last 250 mm can not be used

punching unit (2x)

1 punching unit per leg

1 punch per punching unit

adjustable back mark by tooling from from 20-40 mm

hydraulic downholder

direct access for quick change of punches and dies

shearing unit

shearing power 350 kN

single cut

direct access for quick change of shearing blade

hydraulic downholder

CNC control OMRON PLC

colour touchscreen 8"

compact flash card

simplified, intuitive programming

incremental/absolute values

parts, bars and project can be stored on the CF card

tooling package

1 shearing blade

1 punch and die holder for back mark 30 mm for Y axis

1 punch and die holder for back mark 30 mm for Z axis

2 set round punches and dies

optional equipment:

| automatic side loader | € | 24.400,- |

| up to 6 anlges | ||

| max. angle length 12 m | ||

| composed by 5 side loaders and 4 conveyers, | ||

| the two first ones are motorized | ||

| fully controlled by the CNC | ||

| additional roller conveyer | € | 2.300,- |

| extended tooling package | € | 2.200,- |

| 2 set punch and die holder for 20 mm back mark | ||

| 40 mm back mark | ||

| 5 Set punches and dies Dm. 10 mm | ||

| 5 Set punches and dies Dm. 15 mm | ||

| 1 shearing blade | ||

| Software LINE PRO NETe | 4.900,- | |

| simple, intuitive input, visual | ||

| grafic display | ||

| absolute / incremental | ||

| database for parts and projects | ||

| import of dxf and dstv files | ||

| different languages | ||

| PC software, file exchange by compact flash card | ||

| or LAN (network card not included) | ||

| Nesting | ||

| network card | € | 1.600,- |

| file import from external Line Pro software | ||

| in the machine control | ||

| set in function and teaching of the operator | € | 4.300,- |

| (flight and hotel not included) | ||

| ALTERNATIVE: | ||

| Model C2PL 80 | € | 74.200,- |

| min. angle 40x40x4 mm | ||

| max. angle 80x80x8 mm | ||

| number of punching stations: 1 (1 per leg) | ||

| max. diam./thickness: 25 in 8 mm | ||

| punching force 340 kN | ||

| cutting force 650 kN | ||

| back mark 20 - 50 mm |

Furthe CNC lines for angle and/or flat

steel processing on request

all capacities based on mild steel 450 N/mm²

Further information

Brochures

Notice

Prices ex location, excluding VAT.

The General Terms and Conditions of Delivery of the Austrian Association of the Machine and Steel Construction Industry apply.

We only sell under retention of title, the goods remain our unrestricted property until they have been paid for in full.

Price changes and errors excepted.